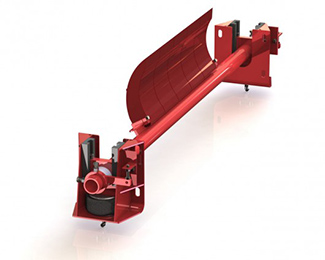

Air Bag Tension Polyurethane Primary Belt Cleaner

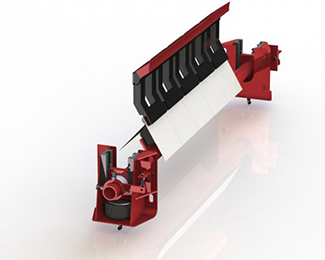

The MATO MUP2 polyurethane primary belt cleaner is designed to be aggressive but friendly to the conveyor belt. The MUP2 returns up to 95% of the bulk material to the mainstream production flow being conveyed.

The air operated end assembly offers a constant blade pressure to the conveyor belt’s surface for the entire life of the polyurethane blade, eliminating continuous blade adjustment and maintenance. Note, if air is not available the air bag end assembly can also be tensioned by using water pressure from the main supply line. See your local MATO representative for more details.

The MUP2 polyurethane primary belt cleaner has two standard types of tensioning devices available. Spring tension assembly or air operated assembly, for the most reliable and effective tensioning methods available in today's market.

Polyurethane Blades

The MUP2 has the polyurethane grades available to choose from. They can be used in underground coal mines with stringent fire resistant, antistatic requirements, as well as surface applications with aggressive products being conveyed, to high temperature or even food grade applications. MATO has also recently incorporated a polyurethane blade suitable for dry applications with a built-in lubrication system to reduce the chances of chattering whilst running on dry conveyor belts.

Air Bag Tension

The air bag end assembly is one of our latest designs in constant performance for belt cleaner tensioning devices. This unique design of the air bag system for primary and secondary cleaners is by far our most successful tensioning device in today’s market.

When used on our MUP2 primary cleaners the blade contact remains at is today's 15 degrees set up for the entire blade, this improves the cleaning efficiency throughout the life of the polyurethane blade.