-

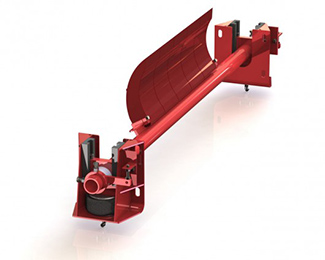

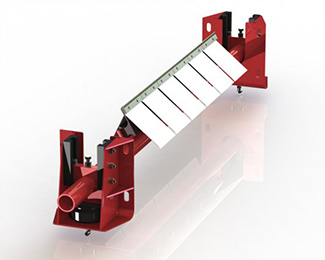

MUP2 Spring Tension Primary Cleaner

-

Air Bag Tension Polyurethane Primary Belt Cleaner

The MATO MUP2 polyurethane primary belt cleaner is designed to be aggressive but friendly to the conveyor belt. The MUP2 returns up to 95% of the bulk material to the mainstream production flow being conveyed. The air operated end assembly offers a constant blade pressure to the conveyor belt’s surface for the entire life of the polyurethane blade, eliminating continuous blade adjustment and maintenance. Note, if air is not available the air bag end assembly can also be tensioned by using water pressure from the main supply line. See your local MATO representative for more details. The MUP2 polyurethane primary belt cleaner has two standard types of tensioning devices available. Spring tension assembly or air operated assembly, for the most reliable and effective tensioning methods available in today's market.Polyurethane Blades

The MUP2 has the polyurethane grades available to choose from. They can be used in underground coal mines with stringent fire resistant, antistatic requirements, as well as surface applications with aggressive products being conveyed, to high temperature or even food grade applications. MATO has also recently incorporated a polyurethane blade suitable for dry applications with a built-in lubrication system to reduce the chances of chattering whilst running on dry conveyor belts.Air Bag Tension

The air bag end assembly is one of our latest designs in constant performance for belt cleaner tensioning devices. This unique design of the air bag system for primary and secondary cleaners is by far our most successful tensioning device in today’s market. When used on our MUP2 primary cleaners the blade contact remains at is today's 15 degrees set up for the entire blade, this improves the cleaning efficiency throughout the life of the polyurethane blade. -

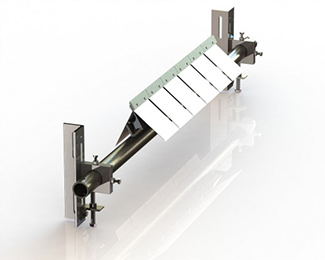

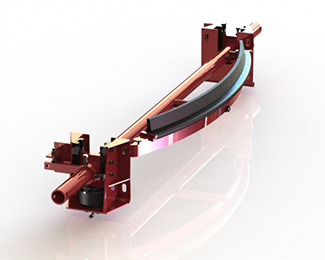

MUS4 Bolt Tension Stainless Secondary Cleaner

The MATO MUS4 belt cleaner is one of our latest designed belt cleaners and offers our M-TRAK slide on cushion and blade for easy installation and maintenance. The unique M-TRAK is designed to eliminate long maintenance down times and ensures that all blade alignments are 100% true across the entire conveyor belt width. Blade replacement is very simple with the design of the slide on and slides off principle, meaning no special tools or training is required when maintenance is performed. The MUS4 cleaner is specifically designed to be installed on conveyor systems that are either fully spliced or have mechanical belt fasteners. The MUS4 cleaner has a low minimum height requirement for installation.Polyurethane Blades

These are 85A shore hardness, FRAS approved polyurethane.Bolt Tension

The MATO standard bolt tension assembly allows for easy adjustment during the initial setup of the blade and for ongoing changes to the blade height as it wears. Bolt tension assemblies work very well with a cushioned or flexible blade system.Features and Benefits:

- Easy blade replacement

- Outstanding performance on sticky material

- Clog free operation

- Various blade options

- Multi-bladed with individual cushion mounts

- Can operate on reversing belt

-

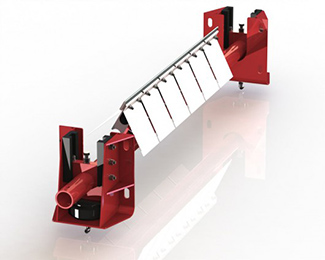

MCS4 Bolt Tension Stainless Secondary Belt Cleaner

The MATO MCS4 belt cleaning unit is a multi-bladed inline system, each blade is individually mounted with a rubber tensioning cushion to ensure even blade pressure and constant tip contact across the belt surface. The cleaner is designed to be slim-lined so it can fit into almost any position, taking up the minimal amount of room possible. The MCS4 secondary cleaner is suitable for all applications and works extremely well on high speed fully vulcanised belts or mechanically fastened belts, ensuring a clog-free operation.Tungsten Carbide Blades

MATO offers different grades of tungsten carbide to suit each application. For example, tungsten impact where the belts have mechanically fastened joints, or tungsten long life for higher speed belts with abrasive materials.Bolt Tension

The MATO standard bolt tension assembly allows for easy adjustment during the initial setup of the blade and for ongoing changes to the blade height as it wears. Bolt tension assemblies work very well with a cushioned or flexible blade system.Features and Benefits:

- Fits into confined spaces

- Outstanding performance on sticky material

- Easy installation and maintenance

- Various blade options

- Multi-bladed with individual cushion mounts

-

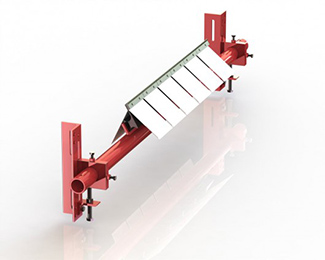

MCS4 Air Bag Tension Secondary Belt Cleaner

The MATO MCS4 belt cleaning unit is a multi-bladed inline system, each blade is individually mounted with a rubber tensioning cushion to ensure even blade pressure and constant tip contact across the belt surface. The cleaner is designed to be slim-lined so it can fit into almost any position, taking up the minimal amount of room possible. The MCS4 secondary cleaner is suitable for all applications and works extremely well on high speed fully vulcanised belts or mechanically fastened belts, ensuring a clog free operation. The cleaner is easy to install and maintain and can be virtually installed anywhere on the belt.Tungsten Carbide Blades

MATO offers different grades of tungsten carbide to suit each application. For example, tungsten impact where the belts have mechanically fastened joints or tungsten long life for higher speed belts with abrasive materials.Air Bag Tension

The air bag end assembly is one of our latest designs in constant performance for belt cleaner tensioning devices. This unique design of the airbag system for primary and secondary cleaners is by far our most successful tensioning device in today’s market. -

MCS2 Bolt Tension Stainless Secondary Belt Cleaner

The MATO MCS2 belt cleaning unit is the multi-bladed in-line system. Each blade is individually mounted with a rubber tensioning cushion to ensure even blade pressure and constant tip contact across the belt surface.Tungsten Carbide Blades

MATO offers different grades of tungsten carbide to suit each application. For example, tungsten impact where the belts have mechanically fastened joints or tungsten long life for higher speed belts with abrasive materials.Bolt Tension

The MATO standard bolt tension assembly allows for easy adjustment during the initial setup of the blade and for ongoing changes to the blade height as it wears. Bolt tension assemblies work very well with a cushioned or flexible blade system. -

MCS2 Bolt Tension Secondary Belt Cleaner

The MATO MCS2 belt cleaning unit is a multi-bladed in-line system. Each blade is individually mounted with a rubber tensioning cushion to ensure even blade pressure, and constant tip contact across the belt surface.Tungsten Carbide Blades

MATO offers different grades of tungsten carbide to suit each application. For example, tungsten impact where the belts have mechanically fastened joints or tungsten long life for higher speed belts with abrasive materials.Bolt Tension

The MATO standard bolt tension assembly allows for easy adjustment during the initial setup of the blade and for ongoing changes to the blade height as it wears. Bolt tension assemblies work very well with a cushioned or flexible blade system. -

MCS2 Air Bag Tension Secondary Belt Cleaner

The MATO MCS2 belt cleaning unit is the multi-bladed in-line system. Each blade is individually mounted with a rubber tensioning cushion to ensure even blade pressure and constant tip contact across the belt surface.Tungsten Carbide Blades

MATO offers different grades of tungsten carbide to suit each application. For example, tungsten impact where the belts have mechanically fastened joints or tungsten long life for higher speed belts with abrasive materials.Air Bag Tension

The air bag end assembly is one of our latest designs in constant performance for belt cleaner tensioning devices. This unique design of the airbag system for primary and secondary cleaners is by far our most successful tensioning device in today’s market. -

MCS1 Spring Tension Secondary Belt Cleaner

The MATO MCS1 unique belt cleaning system is designed to allow the cleaner blade to act independently to conform to the conveyor belt surface. The mounting arm arrangement encompassing the tension spring system allows each side of the cleaner to act independently of each other thus providing the even distribution of cleaner blade pressure on the belt while allowing the blade to follow any variation in the belt surface. The unique concept of the MATO MCS1 belt cleaner is such that the cleaner blade is free to move on the belt, while still maintaining relatively constant pressure across its cleaning surface.Polyurethane Blades

There are a variety of polyurethane grades to choose from to best suit the application for the cleaner whether for surface or underground mining conditions.Spring Tension

The tension spring assembly allows for constant tension to be applied to the cleaner unit, to cater for blade wear or greater movement for the blade surface on the head drum. This reduces the maintenance frequency for adjustment. -

MCS1 Air Bag Secondary Belt Cleaner

The MATO MCS1 unique belt cleaning system is designed to allow the cleaner blade to act independently to conform to the conveyor belt surface. The mounting arm arrangement encompassing the air bag system allows each side of the cleaner to act independently thus providing the even distribution of cleaner blade pressure on the belt while allowing the blade to follow any variation in the belt surface. The unique concept of the MATO MCS1 belt cleaner is such that the cleaner blade is free to move on the belt, while still maintaining relatively constant pressure across its cleaning surface.Polyurethane Blades

There are a variety of polyurethane grades to choose from to best suit the application for the cleaner whether for surface or underground mining conditions.Air Bag Tension

The air bag end assembly is one of our latest designs in constant performance for belt cleaner tensioning devices. This unique design of the air bag system for primary and secondary cleaners is by far our most successful tensioning device in today’s market. -

The MATO MCR2 diagonal plough has all the same features of the MCR1 plough, however one blade is designed to cover the entire width of the conveyor belt. This unit allows for all the materials removed by the plough to be deposited to the desired side of the conveyor belt. The MATO MCR2 diagonal plough is easily changed from a right-hand side configuration to left-hand side unit, as all the cleaner blades are interchangeable.

Features and Benefits:

- Single direction discharge

- Economical

- Ease of installation

- Free floating

-

The MATO MCR1 vee plough is an economical free floating returns plough and is best installed prior to any returns belt pulley, tail pulley or loop take up installations. The MCR1 has a robust construction, allowing for easy installation and recovery if needed. The MCR1 is supported by four chain anchor points to fix to any conveyor structure, thus allowing the unit to free float with varying belt conditions.

Features and Benefits:

- Easy blade replacement

- Economical

- Ease of installation

- Free floating