-

-

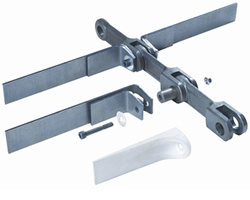

Stainless Spring Tension Pre Belt Cleaner

The MATO MCP1 primary belt cleaner is an aggressive head drum cleaner consisting of multiple blade sections, in line, mounted just under the tangential centre line of the head pulley, to remove the bulk of the carryback material to return to the main flow of product being conveyed. The MCP1 cleaner is mounted underneath the head drum to ensure no material build-up occurs on the cleaner unit, and to eliminate the risk of damage from the cleaner to the belt. Each blade is individually mounted with a rubber tensioning cushion to ensure even blade pressure across the face of the head drum. Tungsten carbide blades are used for fully vulcanised belts and polyurethane blades are used for mechanically fastened belts.Polyurethane Blades

There are a number of polyurethane blade grades to choose from. Polyurethane blades can be used in underground coal mines with stringent fire resistant, antistatic requirements, as well as surface applications with aggressive products being conveyed, to high temperature or even food grade applications. Mato has also incorporated a polyurethane blade suitable for very dry applications with the polyurethane blade being used having its own inbuilt lubrication element to reduce the chances of chattering whilst running on dry conveyor belts.Spring Tension

The tension spring assembly allows for constant tension to be applied to the cleaner unit, to cater for blade wear or greater movement for the blade surface on the head drum. This reduces the maintenance frequency for adjustment. -

Stainless Spring Tension Pre Belt Cleaner

The MATO MCP1 primary belt cleaner is an aggressive head drum cleaner consisting of multiple blade sections, in line, mounted just under the tangential centre line of the head pulley, to remove the bulk of the carry back material to return to the main flow of product being conveyed. The MCP1 cleaner is mounted underneath the head drum to ensure no material build up occurs on the cleaner unit, and to eliminate the risk of damage from the cleaner to the belt. Each blade is individually mounted with a rubber tensioning cushion to ensure even blade pressure across the face of the head drum. Tungsten carbide blades are used for fully vulcanised belts and polyurethane blades are used for mechanically fastened belts.Polyurethane Blades

There are a number of polyurethane blade grades to choose from. Polyurethane blades can be used in underground coal mines with stringent fire resistant, antistatic requirements, as well as surface applications with aggressive products being conveyed, to high temperature or even food grade applications. Mato has also incorporated a polyurethane blade suitable for very dry applications with the polyurethane blade being used having its own inbuilt lubrication element to reduce the chances of chattering whilst running on dry conveyor belts.Spring Tension

The tension spring assembly allows for constant tension to be applied on the cleaner unit, to cater for blade wear or greater movement for the blade surface on the head drum. This reduces the maintenance frequency for adjustment. -

Spring Tension Pre Belt Cleaner

The MATO MCP1 primary belt cleaner is an aggressive head drum cleaner consisting of multiple blade sections, in line, mounted just under the tangential centre line of the head pulley, to remove the bulk of the carryback material to return to the main flow of product being conveyed. The MCP1 cleaner is mounted underneath the head drum to ensure no material build-up occurs on the cleaner unit, and to eliminate the risk of damage from the cleaner to the belt. Each blade is individually mounted with a rubber tensioning cushion to ensure even blade pressure across the face of the head drum. Tungsten carbide blades are used for fully vulcanised belts and polyurethane blades are used for mechanically fastened belts.Polyurethane Blades

There are a number of polyurethane blade grades to choose from. Polyurethane blades can be used in underground coal mines with stringent fire resistant, antistatic requirements, as well as surface applications with aggressive products being conveyed, to high temperature or even food grade applications. Mato has also incorporated a polyurethane blade suitable for very dry applications with the polyurethane blade being used having its own inbuilt lubrication element to reduce the chances of chattering whilst running on dry conveyor belts.Spring Tension

The tension spring assembly allows for constant tension to be applied to the cleaner unit, to cater for blade wear or greater movement for the blade surface on the head drum. This reduces the maintenance frequency for adjustment. -

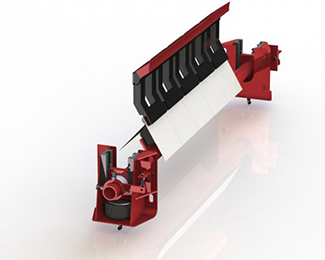

MCP1 Air Bag Tension Pre Belt Cleaner

The MATO MCP1 primary belt cleaner is an aggressive head drum cleaner consisting of multiple blade sections, in line, mounted just under the tangential centre line of the head pulley, to remove the bulk of the carryback material to return to the main flow of product being conveyed. The MCP1 cleaner is mounted underneath the head drum to ensure no material build-up occurs on the cleaner unit, and to eliminate the risk of damage from the cleaner to the belt. Each blade is individually mounted with a rubber tensioning cushion to ensure even blade pressure across the face of the head drum. Tungsten carbide blades are used for fully vulcanised belts and polyurethane blades are used for mechanically fastened belts.Polyurethane Blades

There are a number of polyurethane blade grades to choose from. Polyurethane blades can be used in underground coal mines with stringent fire resistant, antistatic requirements, as well as surface applications with aggressive products being conveyed, to high temperature or even food grade applications. MATO has also incorporated a polyurethane blade suitable for very dry applications with an inbuilt lubrication element to reduce the chances of chattering whilst running on dry conveyor belts.Air Bag Tension

The air bag end assembly is one of our latest designs in constant performance for belt cleaner tensioning devices. This unique design of the air bag system for primary and secondary cleaners is by far our most successful tensioning device in today’s market. -

Forged Chain Links

A complete line of drop forged conveyor chain and accessories in various sizes. Simple to use and robust, which is what your production line needs. For the Toughest Applications with Minimum Breaking Load Strengths of between 33,000 lbs. (150 kn) to 158,000 lbs. (700kn). Specifications FEATURES: Minimum Breaking Load Strengths: Range from 33,000 lbs. (150 kn) to 158,000 lbs. (700kn) Availability:- Chain without flights - from stock

- Chain with flights quick delivery

-

Quick Release Conveyor Skirting Clamp

The challenge is always to contain spillage and control dust at the transfer point areas, regardless of the bulk material, with any conveyor belt operation. Quick release conveyor skirting clamp that help eliminate spillage and dust in the conveyor transfer point. Make it easy to eliminate loading-point spillage on any conveyor loading site. We are a recognised industry leader in conveyor skirting system products.- Skirting material is adjusted in minutes

- Clamp adjustments are made quickly, easily and safely

- Low cost

- Positive fixing

- No springs to jam or break

-

CONVEYOR IDLERS

Conveyor, impact & return belt idlers assemblies

Conveyor Technology Services supply conveyor idlers, impact idlers and return belt idlers assemblies, through such manufacturers as DRC Rollers, Prok Group, and Tyton Idlers, and Special roller configurations. Conveyor Technology Services supply polymer rollers. These rollers are a new generation, heavy duty alternative to steel rollers. The rollers are constructed of glass-filled fibre, high density, polyethylene (HDPE), which has proven to substantially outlast steel rollers. The significant advantages which apply to applications utilising K-Poly Conveyor Rollers are:

- Less damage to belting in event of roller collapse

- Noise reduction of poly surface up to 9dba reduction over conventional steel rollers

- Wear resistant

- Reduced material build up upon roller shell

- Up to 50% lighter than conventional idlers

-

CONVEYOR BELT MAINTENANCE

Choose from our selection of belt maintenance products including pulley lagging, conveyor skirting clamps, belt cutters, belt lifters, belt squares and track swivels. We use engineered products and services to provide our customers with the best solutions for their conveyor material handling. We offer a comprehensive selection of quality belt maintenance products for the material handling industry. We also provide customers with unsurpassed product and application support.

Conveyor Skirting Clamps - Quick release conveyor skirting clamp that helps eliminate spillage and dust in the conveyor transfer point.

Pulley Lagging - Designed, developed and manufactured in Australia for the harsh conditions of all mining industries.

Conveyor Technology Services is synonymous with offering innovative conveyor hardware solutions. The new technology conveyor skirt products, pulley lagging and tracking products offer significantly longer life and lower friction and will definitely reduce belt damage, plus lower your conveyor maintenance and spillage cleanup costs.

Tracking Products - Belt trackers that are designed to suit the individual needs of the conveyor application.

-

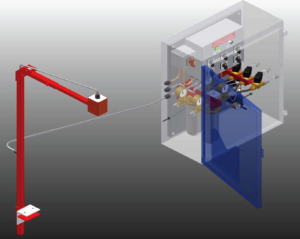

CONTROL UNITS

Water Control Units & Stations

Inline Water Control Unit

Spray Board:

Spray Board:

- The Inline Water Control Unit is a simple system to control the use of water sprays to operate on either belt running or product being conveyed.

Double Solenoid Water Control Manifold

Spray Board:

Spray Board:

- Our Solenoid Water Manifold is an upgraded version of our Inline Water Control Unit, to encompass a filtration station and a manual by-pass connection in case of power failures.

Ultrasonic Water Control and Belt Cleaner Control Station

Ultrasonic Control:

Ultrasonic Control:

- An ultrasonic beam senses product being conveyed to activate a variety of water or air valves for dust suppression and conveyor belt cleaner control

- The system has variable options for power supply, and function, based on either belt running or products being detected

-

CHAIN CONVEYORS

Chain Links, Flights, Sprockets and Trailers

We have Primary Cleaning Systems to suit most applications and providing easy and effective maintenance of industrial equipment conveyor belt systems.Forged Chain Links

Chain & Flight Systems

Sprockets & Trailers

Forged Chain

4B drop forged chain is made of special heat treated alloy steel case hardened to Rockwell C57 with a ductile core hardness of Rockwell C40. Heat treating is a complex process that is done to provide the optimum chain link with a more fractured resilient ductile core for shock resistance, and an extremely hard exterior surface for superior wear resistance. 4B drop forged chain is backed by an international network of companies with over 120 years of experience, and a global team of engineers that can provide you with practical solutions for all your material handling applications.Drop Forged Chain

Link and flight assembly are made easy by using a standard bolt and nut with a high strength hollow pin. There are no circlips to become loose and there is no intricate assembly. There is no welding required on the flights, no need to remove the chain from the conveyor for installation, and no issues with strength. Just bolt the links and the flights together. It’s easy, simple and reliable!

Flexal is an elastic device for products loading on belt conveyors. It consists of cross belt elastic straps which, through their flexibility and their elongation ability, absorb impact energy and weight of loaded products.

The straps, more or less numerous, are supported by a metal framework, adjustable in all 3 dimensions in order to fit the system to every trough angle, from 20 to 70°. Each strap is fitted with sliding pads made of very high molecular weight HDPE. They are replaceable and their number is flexible, depending on the application.

Flexal is an elastic device for products loading on belt conveyors. It consists of cross belt elastic straps which, through their flexibility and their elongation ability, absorb impact energy and weight of loaded products.

The straps, more or less numerous, are supported by a metal framework, adjustable in all 3 dimensions in order to fit the system to every trough angle, from 20 to 70°. Each strap is fitted with sliding pads made of very high molecular weight HDPE. They are replaceable and their number is flexible, depending on the application.

Spray Board:

Spray Board:

Spray Board:

Spray Board:

Ultrasonic Control:

Ultrasonic Control: