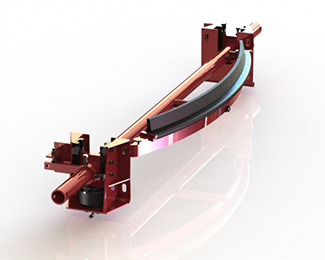

MCS1 Spring Tension Secondary Belt Cleaner

The MATO MCS1 unique belt cleaning system is designed to allow the cleaner blade to act independently to conform to the conveyor belt surface.

The mounting arm arrangement encompassing the tension spring system allows each side of the cleaner to act independently of each other thus providing the even distribution of cleaner blade pressure on the belt while allowing the blade to follow any variation in the belt surface.

The unique concept of the MATO MCS1 belt cleaner is such that the cleaner blade is free to move on the belt, while still maintaining relatively constant pressure across its cleaning surface.

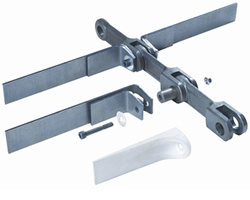

Polyurethane Blades

There are a variety of polyurethane grades to choose from to best suit the application for the cleaner whether for surface or underground mining conditions.

Spring Tension

The tension spring assembly allows for constant tension to be applied to the cleaner unit, to cater for blade wear or greater movement for the blade surface on the head drum. This reduces the maintenance frequency for adjustment.