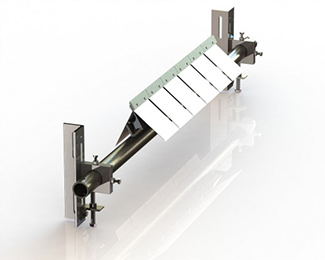

Bolt Tension Tungsten Carbide Pre Belt Cleaner

The MATO MCP1 Belt Cleaning Unit is an aggressive head drum cleaner consisting of a multiple blade section, in line, mounted just under the Tangential centre line of the head pulley, to remove the bulk of the carryback material to return to the main flow of product being conveyed.

The MCP1 cleaner is mounted underneath the head drum to ensure no material build-up occurs on the cleaner unit, and to eliminate the risk of damage from the cleaner to the belt.

Each blade is individually mounted with a rubber tensioning cushion to ensure even blade pressure across the face of the head drum. Tungsten carbide blades are used for fully Vulcanised Belts and Polyurethane Blades are used for mechanically fastened belts.

Tungsten Carbide Blades

MATO offers different grades of tungsten carbide to suit each application. For example, tungsten impact when used with aggressive products or belts, tungsten long life for high speed, abrasive, applications (not for use with mechanical fasteners).

Bolt Tension

The MATO standard bolt tension assembly allows for easy adjustment during the initial setup of the blade and for ongoing changes to the blade height as it wears. Bolt tension assemblies work very well with a cushioned or flexible blade system.