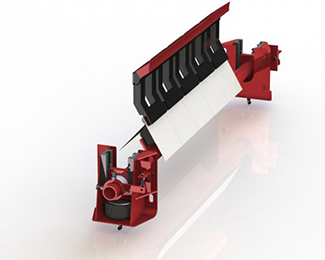

MCP1 Air Bag Tension Pre Belt Cleaner

The MATO MCP1 primary belt cleaner is an aggressive head drum cleaner consisting of multiple blade sections, in line, mounted just under the tangential centre line of the head pulley, to remove the bulk of the carryback material to return to the main flow of product being conveyed.

The MCP1 cleaner is mounted underneath the head drum to ensure no material build-up occurs on the cleaner unit, and to eliminate the risk of damage from the cleaner to the belt.

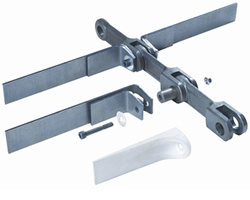

Each blade is individually mounted with a rubber tensioning cushion to ensure even blade pressure across the face of the head drum. Tungsten carbide blades are used for fully vulcanised belts and polyurethane blades are used for mechanically fastened belts.

Polyurethane Blades

There are a number of polyurethane blade grades to choose from. Polyurethane blades can be used in underground coal mines with stringent fire resistant, antistatic requirements, as well as surface applications with aggressive products being conveyed, to high temperature or even food grade applications.

MATO has also incorporated a polyurethane blade suitable for very dry applications with an inbuilt lubrication element to reduce the chances of chattering whilst running on dry conveyor belts.

Air Bag Tension

The air bag end assembly is one of our latest designs in constant performance for belt cleaner tensioning devices. This unique design of the air bag system for primary and secondary cleaners is by far our most successful tensioning device in today’s market.