CONVEYOR BELT MAINTENANCE

Choose from our selection of belt maintenance products including pulley lagging, conveyor skirting clamps, belt cutters, belt lifters, belt squares and track swivels. We use engineered products and services to provide our customers with the best solutions for their conveyor material handling. We offer a comprehensive selection of quality belt maintenance products for the material handling industry. We also provide customers with unsurpassed product and application support.

Conveyor Skirting Clamps - Quick release conveyor skirting clamp that helps eliminate spillage and dust in the conveyor transfer point.

Pulley Lagging - Designed, developed and manufactured in Australia for the harsh conditions of all mining industries.

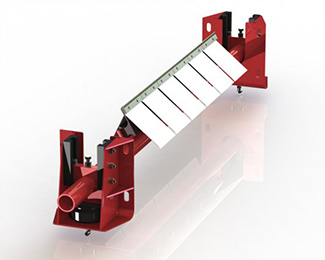

Tracking Products - Belt trackers that are designed to suit the individual needs of the conveyor application.

Can be used for belts up to 19mm thick and is available in standard sizes of 900, 1200 and 1500mm width.

Can be used for belts up to 19mm thick and is available in standard sizes of 900, 1200 and 1500mm width.

Can be used for belts 15-30mm thick and is available in standard sizes of 1200, 1500 and 1800mm width.

Can be used for belts 15-30mm thick and is available in standard sizes of 1200, 1500 and 1800mm width.