-

-

Belt Fasteners Belt Lacing Systems & Repair Fasteners

We are one of the world's leading suppliers of mechanical fasteners used in mining & servicing the growing need for mechanical fasteners in Australia. It is the preferred choice in most mining and material handling operations worldwide, used in coal mining and hard rock applications. Our fasteners & associated products withstand the harshest conditions without compromising performance. Belt Lacing Systems for Light Tensile Conveyor Belts up to 750 kN/m -

MUP2 Spring Tension Primary Cleaner

-

Link Specification

A - Alloy steel - Case hardened, surface hardness RC 57min AD - Alloy steel - Through hardened (for higher U.T.S.) C - Carbon steel - Case hardened, surface hardness RC 57Pin Specification

Alloy steel - Case hardened, surface hardness RC 57 min. Effective case depth 0.6mmFeatures:

The Bolt N Go flight system is a revolutionary assembly method for drop forged and round link conveyor chain. Easy and simple assembly on site or in the shop Precise calculated flight bending forces No welding required Guaranteed and reliable pin attachment Condensed storage and shipping costs Forged chain and round link chain compatible Plastic flight option (high-density polyethene or nylon) Steel flight option (drop forged chain only) -

Forged Chain Links

A complete line of drop forged conveyor chain and accessories in various sizes. Simple to use and robust, which is what your production line needs. For the Toughest Applications with Minimum Breaking Load Strengths of between 33,000 lbs. (150 kn) to 158,000 lbs. (700kn). Specifications FEATURES: Minimum Breaking Load Strengths: Range from 33,000 lbs. (150 kn) to 158,000 lbs. (700kn) Availability:- Chain without flights - from stock

- Chain with flights quick delivery

-

CONVEYOR IDLERS

Conveyor, impact & return belt idlers assemblies

Conveyor Technology Services supply conveyor idlers, impact idlers and return belt idlers assemblies, through such manufacturers as DRC Rollers, Prok Group, and Tyton Idlers, and Special roller configurations. Conveyor Technology Services supply polymer rollers. These rollers are a new generation, heavy duty alternative to steel rollers. The rollers are constructed of glass-filled fibre, high density, polyethylene (HDPE), which has proven to substantially outlast steel rollers. The significant advantages which apply to applications utilising K-Poly Conveyor Rollers are:

- Less damage to belting in event of roller collapse

- Noise reduction of poly surface up to 9dba reduction over conventional steel rollers

- Wear resistant

- Reduced material build up upon roller shell

- Up to 50% lighter than conventional idlers

-

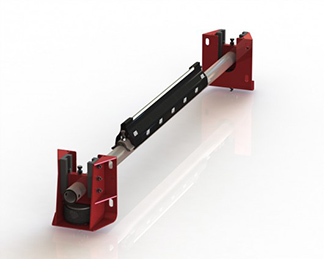

MUS3 Air Bag Tension Secondary Belt Cleaner

The MATO MUS3 belt cleaner is one of our latest designed belt cleaners and offers our new M-TRAK slide on cushion and blade for easy installation and maintenance. The unique M-TRAK is designed to eliminate long maintenance down times and ensures that all blade alignments are 100% true across the entire conveyor belt width. When using our air tensioned end assemblies, blade replacement is very simple with the design of the slide on and slide off principle, meaning no special tools or training is required when maintenance is performed.Cushion with Carbide Blades

The MUS3 cleaner is specifically designed to be installed on conveyor systems that are either fully spliced or have mechanical belt fasteners. The design of our MUS3 cleaners has the tungsten carbide blade insert that can withstand the impact of mechanical fasteners which are used in most longwall applications in underground coal mining. One of the main features of the MUS3 cleaner is the low minimum height requirement required for this cleanerAir Bag Tension

The air bag end assembly is one of our latest designs in constant performance for belt cleaner tensioning devices. This unique design of the air bag system for primary and secondary cleaners is by far our most successful tensioning device in today’s market. -

Belt Fasteners Belt Lacing Systems & Repair Fasteners

We are one of the world's leading suppliers of mechanical fasteners used in mining & servicing the growing need for mechanical fasteners in Australia. It is the preferred choice in most mining and material handling operations worldwide, used in coal mining and hard rock applications. Our fasteners & associated products withstand the harshest conditions without compromising performance. Belt Lacing Systems for High Tensile Textile Conveyor Belts above 750 kN/m -

SKIRTS AND GUARDS

Skirting Clamps & Safety Rail Systems

Prevent accidents and guard the conveyor belt with these quick installation time skirts and guards.- Quick Release Conveyor Skirting Clamp

- Modular Safety Rail System

Modular Safety Rail System

- Quick installation time

- Easy access to loop take up areas

- Easy access to Drive units

- 100% Retrievable

- No heavy lifting, or removing guards

- Can be used as barriers, to restrict access

-

The MATO MCR1 vee plough is an economical free floating returns plough and is best installed prior to any returns belt pulley, tail pulley or loop take up installations. The MCR1 has a robust construction, allowing for easy installation and recovery if needed. The MCR1 is supported by four chain anchor points to fix to any conveyor structure, thus allowing the unit to free float with varying belt conditions.

Features and Benefits:

- Easy blade replacement

- Economical

- Ease of installation

- Free floating

-

PARTS AND ACCESSORIES Repair Kits, Cutters and Covers

Our parts ensure your conveyor equipment lasts years on. We supply conveyor equipment and parts ensuring your system is productive and efficient.Belt Cutters

MR Type Belt Cutter:

Can be used for belts up to 19mm thick and is available in standard sizes of 900, 1200 and 1500mm width.

Can be used for belts up to 19mm thick and is available in standard sizes of 900, 1200 and 1500mm width.

Heavy Duty Belt Cutter

Can be used for belts 15-30mm thick and is available in standard sizes of 1200, 1500 and 1800mm width.

Can be used for belts 15-30mm thick and is available in standard sizes of 1200, 1500 and 1800mm width.

Pocket Boot Covers

Long Wall Pocket Boot Covers

- Reduces excessive down time

- Keeps L/W chock base leg pockets free of debris

- No hydraulic damage to fittings or hoses

- No leg damage

- No restriction to operation

- Allows complete raising and lowering of chock canopy

MATO Poly Repair Kit

- Dual cartridge system to allow you to use only what you need

- Available in 300mL and 600mL sizes

- For applications on worn or damaged conveyor belts, mechanical fastener coverage or where a rubber repair is required

- Primers and solvents also available, for various bonding applications

Handsaver

- Provides a safe and comfortable method of handling awkward objects and saves trapped fingers and cut hands

- Flats, channels, angles, tubes, rounds, H sections, conveyor belting may all be lifted and dragged easily, safely and quickly with this versatile tool

- Corrosion resistant finish

T Square

The MATO square is used in conjunction with the belt knife for cutting the belt end square to the edge of the belt. The squaring angle contains a slot to guide the knife blade; this facilitates a straight cut and safe operation of the knife.

The MATO square is used in conjunction with the belt knife for cutting the belt end square to the edge of the belt. The squaring angle contains a slot to guide the knife blade; this facilitates a straight cut and safe operation of the knife. -

The MATO MCR2 diagonal plough has all the same features of the MCR1 plough, however one blade is designed to cover the entire width of the conveyor belt. This unit allows for all the materials removed by the plough to be deposited to the desired side of the conveyor belt. The MATO MCR2 diagonal plough is easily changed from a right-hand side configuration to left-hand side unit, as all the cleaner blades are interchangeable.

Features and Benefits:

- Single direction discharge

- Economical

- Ease of installation

- Free floating

Can be used for belts up to 19mm thick and is available in standard sizes of 900, 1200 and 1500mm width.

Can be used for belts up to 19mm thick and is available in standard sizes of 900, 1200 and 1500mm width.

Can be used for belts 15-30mm thick and is available in standard sizes of 1200, 1500 and 1800mm width.

Can be used for belts 15-30mm thick and is available in standard sizes of 1200, 1500 and 1800mm width.