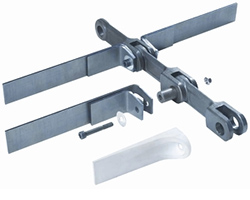

Link Specification

A - Alloy steel - Case hardened, surface hardness RC 57min

AD - Alloy steel - Through hardened (for higher U.T.S.)

C - Carbon steel - Case hardened, surface hardness RC 57

Pin Specification

Alloy steel - Case hardened, surface hardness RC 57 min. Effective case depth 0.6mm

Features:

The Bolt N Go flight system is a revolutionary assembly method for drop forged and round link conveyor chain.

Easy and simple assembly on site or in the shop

Precise calculated flight bending forces

No welding required

Guaranteed and reliable pin attachment

Condensed storage and shipping costs

Forged chain and round link chain compatible

Plastic flight option (high-density polyethene or nylon)

Steel flight option (drop forged chain only)

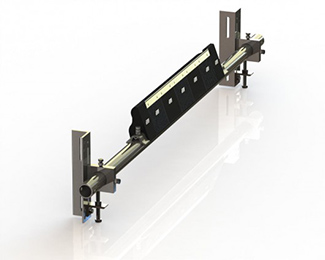

Spray Board:

Spray Board:

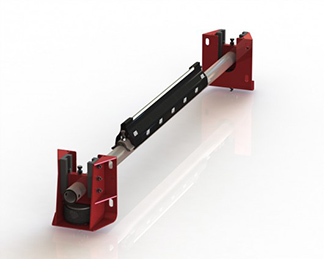

Spray Board:

Spray Board:

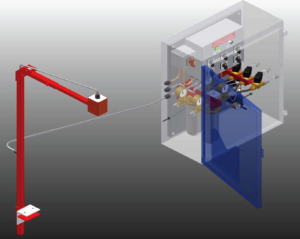

Ultrasonic Control:

Ultrasonic Control:

Can be used for belts up to 19mm thick and is available in standard sizes of 900, 1200 and 1500mm width.

Can be used for belts up to 19mm thick and is available in standard sizes of 900, 1200 and 1500mm width.

Can be used for belts 15-30mm thick and is available in standard sizes of 1200, 1500 and 1800mm width.

Can be used for belts 15-30mm thick and is available in standard sizes of 1200, 1500 and 1800mm width.