-

-

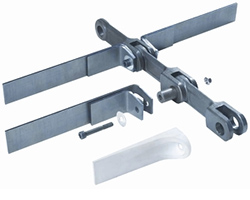

Belt Fasteners Belt Lacing Systems & Repair Fasteners

We are one of the world's leading suppliers of mechanical fasteners used in mining & servicing the growing need for mechanical fasteners in Australia. It is the preferred choice in most mining and material handling operations worldwide, used in coal mining and hard rock applications. Our fasteners & associated products withstand the harshest conditions without compromising performance. Belt Lacing Systems for Light Tensile Conveyor Belts up to 750 kN/m -

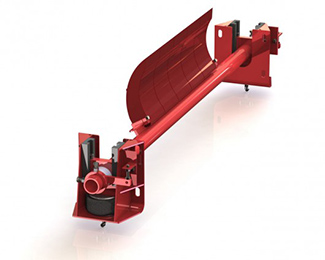

MUP2 Spring Tension Primary Cleaner

-

Link Specification

A - Alloy steel - Case hardened, surface hardness RC 57min AD - Alloy steel - Through hardened (for higher U.T.S.) C - Carbon steel - Case hardened, surface hardness RC 57Pin Specification

Alloy steel - Case hardened, surface hardness RC 57 min. Effective case depth 0.6mmFeatures:

The Bolt N Go flight system is a revolutionary assembly method for drop forged and round link conveyor chain. Easy and simple assembly on site or in the shop Precise calculated flight bending forces No welding required Guaranteed and reliable pin attachment Condensed storage and shipping costs Forged chain and round link chain compatible Plastic flight option (high-density polyethene or nylon) Steel flight option (drop forged chain only) -

Forged Chain Links

A complete line of drop forged conveyor chain and accessories in various sizes. Simple to use and robust, which is what your production line needs. For the Toughest Applications with Minimum Breaking Load Strengths of between 33,000 lbs. (150 kn) to 158,000 lbs. (700kn). Specifications FEATURES: Minimum Breaking Load Strengths: Range from 33,000 lbs. (150 kn) to 158,000 lbs. (700kn) Availability:- Chain without flights - from stock

- Chain with flights quick delivery

-

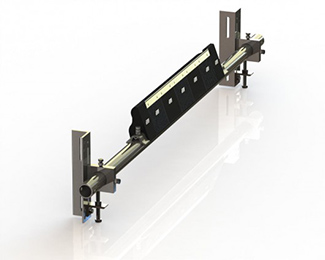

MUS3 Bolt Tension Secondary Belt Cleaner

The MATO MUS3 belt cleaner is one of our latest designed belt cleaners and offers our new M-TRAK slide on cushion & blade for easy installation and maintenance. The unique M-TRAK is designed to eliminate long maintenance down times and ensures that all blade alignments are 100% true across the entire conveyor belt width. Blade replacement is very simple with the design of the slide on and slide of principle, meaning no special tools or training is required when maintenance is performed. The unique design of our MUS3 cushion is based on the principle of a parallelogram whereby the cushion also stays true to the conveyor belts surface and ensures the attacking angle is maintained.Cushion with Carbide Blade

The MUS3 cleaner is specifically designed to be installed on conveyor systems that are either fully spliced or have mechanical belt fasteners. The design of our MUS2 cleaners has the tungsten carbide blade insert that can withstand the impact of mechanical fasteners which are used in most longwall applications in underground coal mining.Bolt Tension

The MATO standard bolt tension assembly allows for easy adjustment during the initial setup of the blade and for ongoing changes to the blade height as it wears. Bolt tension assemblies work very well with a cushioned or flexible blade system. -

BUCKET ELEVATORS

Centrifugal and Continuous Discharge Elevators

Bucket elevators are designed to move flowing powders or bulk solids vertically. Bucket elevators use an endless belt or chain and have a series of buckets attached to it. Bulk material is spread into an inlet hopper. Buckets dig into the material and convey it up and over the head sprocket/pulley, and then throw the material out a discharge throat. Bucket elevators are not self-feeding and are fed at a controlled rate. The buckets are usually where the chain or belt path is vertical or steeply inclined in a single plane. The buckets are returned back down to a tail pulley or sprocket at the bottom.There are four broad classifications of bucket elevators: centrifugal, continuous, positive, and internal discharge. The most commonly used are the centrifugal and continuous discharge elevators. Conveyor Technology Services industrial bucket elevators are made in a variety of shapes, weights and sizes, all utilising centrifugal buckets or continuous buckets. -

MUS4 Bolt Tension Stainless Secondary Cleaner

The MATO MUS4 belt cleaner is one of our latest designed belt cleaners and offers our M-TRAK slide on cushion and blade for easy installation and maintenance. The unique M-TRAK is designed to eliminate long maintenance down times and ensures that all blade alignments are 100% true across the entire conveyor belt width. Blade replacement is very simple with the design of the slide on and slides off principle, meaning no special tools or training is required when maintenance is performed. The MUS4 cleaner is specifically designed to be installed on conveyor systems that are either fully spliced or have mechanical belt fasteners. The MUS4 cleaner has a low minimum height requirement for installation.Polyurethane Blades

These are 85A shore hardness, FRAS approved polyurethane.Bolt Tension

The MATO standard bolt tension assembly allows for easy adjustment during the initial setup of the blade and for ongoing changes to the blade height as it wears. Bolt tension assemblies work very well with a cushioned or flexible blade system. -

Bolt Tension Tungsten Carbide Pre Belt Cleaner

The MATO MCP1 Belt Cleaning Unit is an aggressive head drum cleaner consisting of a multiple blade section, in line, mounted just under the Tangential centre line of the head pulley, to remove the bulk of the carryback material to return to the main flow of product being conveyed. The MCP1 cleaner is mounted underneath the head drum to ensure no material build-up occurs on the cleaner unit, and to eliminate the risk of damage from the cleaner to the belt. Each blade is individually mounted with a rubber tensioning cushion to ensure even blade pressure across the face of the head drum. Tungsten carbide blades are used for fully Vulcanised Belts and Polyurethane Blades are used for mechanically fastened belts.Tungsten Carbide Blades

MATO offers different grades of tungsten carbide to suit each application. For example, tungsten impact when used with aggressive products or belts, tungsten long life for high speed, abrasive, applications (not for use with mechanical fasteners).Bolt Tension

The MATO standard bolt tension assembly allows for easy adjustment during the initial setup of the blade and for ongoing changes to the blade height as it wears. Bolt tension assemblies work very well with a cushioned or flexible blade system. -

MCS2 Bolt Tension Stainless Secondary Belt Cleaner

The MATO MCS2 belt cleaning unit is the multi-bladed in-line system. Each blade is individually mounted with a rubber tensioning cushion to ensure even blade pressure and constant tip contact across the belt surface.Tungsten Carbide Blades

MATO offers different grades of tungsten carbide to suit each application. For example, tungsten impact where the belts have mechanically fastened joints or tungsten long life for higher speed belts with abrasive materials.Bolt Tension

The MATO standard bolt tension assembly allows for easy adjustment during the initial setup of the blade and for ongoing changes to the blade height as it wears. Bolt tension assemblies work very well with a cushioned or flexible blade system. -

Air Bag Tension Polyurethane Primary Belt Cleaner

The MATO MUP2 polyurethane primary belt cleaner is designed to be aggressive but friendly to the conveyor belt. The MUP2 returns up to 95% of the bulk material to the mainstream production flow being conveyed. The air operated end assembly offers a constant blade pressure to the conveyor belt’s surface for the entire life of the polyurethane blade, eliminating continuous blade adjustment and maintenance. Note, if air is not available the air bag end assembly can also be tensioned by using water pressure from the main supply line. See your local MATO representative for more details. The MUP2 polyurethane primary belt cleaner has two standard types of tensioning devices available. Spring tension assembly or air operated assembly, for the most reliable and effective tensioning methods available in today's market.Polyurethane Blades

The MUP2 has the polyurethane grades available to choose from. They can be used in underground coal mines with stringent fire resistant, antistatic requirements, as well as surface applications with aggressive products being conveyed, to high temperature or even food grade applications. MATO has also recently incorporated a polyurethane blade suitable for dry applications with a built-in lubrication system to reduce the chances of chattering whilst running on dry conveyor belts.Air Bag Tension

The air bag end assembly is one of our latest designs in constant performance for belt cleaner tensioning devices. This unique design of the air bag system for primary and secondary cleaners is by far our most successful tensioning device in today’s market. When used on our MUP2 primary cleaners the blade contact remains at is today's 15 degrees set up for the entire blade, this improves the cleaning efficiency throughout the life of the polyurethane blade.

Flexal is an elastic device for products loading on belt conveyors. It consists of cross belt elastic straps which, through their flexibility and their elongation ability, absorb impact energy and weight of loaded products.

The straps, more or less numerous, are supported by a metal framework, adjustable in all 3 dimensions in order to fit the system to every trough angle, from 20 to 70°. Each strap is fitted with sliding pads made of very high molecular weight HDPE. They are replaceable and their number is flexible, depending on the application.

Flexal is an elastic device for products loading on belt conveyors. It consists of cross belt elastic straps which, through their flexibility and their elongation ability, absorb impact energy and weight of loaded products.

The straps, more or less numerous, are supported by a metal framework, adjustable in all 3 dimensions in order to fit the system to every trough angle, from 20 to 70°. Each strap is fitted with sliding pads made of very high molecular weight HDPE. They are replaceable and their number is flexible, depending on the application.